Estimated Reading Time: 5 minutes

Key Takeaways:

- Tolerance compensation is crucial for accurate 3D prints.

- Horizontal expansion helps fit parts snugly together.

- Vertical expansion corrects height discrepancies in prints.

- Making incremental adjustments improves fit and functionality.

Table of Contents:

Understanding Tolerance Compensation in 3D Printing

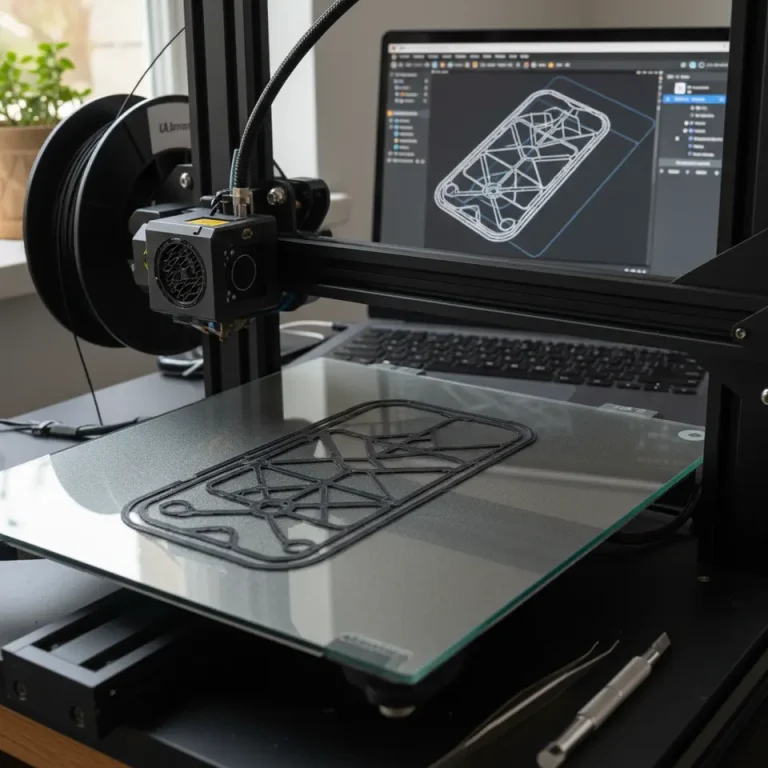

Tolerance compensation refers to the adjustments made in the slicer for deviations commonly found in physical prints compared to their digital counterparts. These deviations arise from various factors, including:

- Printer Calibration: Mechanical tolerances and adjustments can lead to imprecise dimensions.

- Material Shrinkage: Different materials shrink at different rates as they cool, affecting final dimensions.

- Layer Adhesion: Poor layer bonding can alter the overall size, especially on detailed prints.

To ensure that your printed models fit together well and meet design specifications, it’s vital to understand how to manage these adjustments. Here, we will focus on two types of expansions that Cura offers: horizontal and vertical.

Horizontal Expansion

Horizontal expansion compensates for discrepancies in the X and Y axes of your model. When adjusted, this setting can expand or shrink the dimensions of the model across these two horizontal axes. This is particularly useful for parts that need to fit snugly together, such as joints or snap-fit designs.

When to Use Horizontal Expansion

- Snug Fits Needed: When creating parts meant to fit together, such as connectors and clips, applying a horizontal compensation can ensure that parts fit tightly.

- Avoiding Gaps: If you notice gaps or loose fitting in printed assemblies from initial prints, horizontal expansion will help compensate for these issues.

How to Adjust Horizontal Expansion in Cura

- Open Ultimaker Cura.

- Load your 3D model.

- In the Custom settings tab, scroll down to find Horizontal Expansion under the Shell settings.

- Enter a positive value to increase the dimensions (e.g., +0.2 mm) or a negative value for a decrease.

- Click Slice to generate the G-code and prepare for printing.

Vertical Expansion

Vertical expansion, on the other hand, deals with adjustments to the Z-axis. It compensates for vertical dimensional discrepancies and affects the height of your print.

When to Use Vertical Expansion

- Z-axis Discrepancies: If your prints are coming out shorter than intended or if layers are not bonding properly, vertical expansion can compensate for those differences.

- Fine Detail Adjustments: In intricate designs where the height is an essential feature, adjusting vertical dimensions can enhance the fit.

How to Adjust Vertical Expansion in Cura

- Open Ultimaker Cura.

- Load your 3D model.

- Navigate to the Custom settings tab, then find Vertical Expansion beneath the Shell settings.

- Input a positive value (+0.2 mm) to increase height or a negative value to decrease it.

- Click Slice to generate your updated G-code.

Comparison: Horizontal vs. Vertical Expansion

Here’s a quick comparison to sum up when to use each type of compensation:

| Aspect | Horizontal Expansion | Vertical Expansion |

|---|

| Axis Affected | X and Y (width and depth) | Z (height) |

| Use Cases | Fit of parts, connectors, assemblies | Layer adhesion issues, height accuracy |

| Adjustment Impact | Changes width/depth dimensions | Changes height dimension |

Practical Use Cases

- Snap Fit Parts: When designing parts that need to snap together, start with a slight positive horizontal expansion to ensure they fit snugly. On the first print attempt, evaluate the fit, and make incremental adjustments until the desired fit is achieved.

- Multi-part Assemblies: For models made of multiple components, you might experience loose fits when parts are printed separately. Here, both horizontal and vertical adjustments can be evaluated individually to ensure components fit as per design.

Conclusion

Understanding the differences between horizontal and vertical expansion is critical for precision in your 3D prints. By applying these adjustments as needed, you can significantly improve the accuracy of your projects, leading to better functionality and fit of printed parts.

For more on optimizing your Cura settings, check out our in-depth guide on

Cura Slicer Fit Tolerance, which goes into further detail about ensuring components marry correctly and improve your overall print quality.

If you found this guide helpful, explore our blog for more tips on 3D printing optimization, such as reducing print time and enhancing adhesion. You can also follow us on social media for updates and join a community passionate about slicing software and print quality improvement.

Want to dive deeper? Visit our main page for lots of insightful resources:

CuraSlicers.com. Happy printing!

FAQ

What is tolerance compensation?

Tolerance compensation involves adjusting the dimensions of your 3D model to account for deviations in the printed object compared to its intended dimensions.

When should horizontal expansion be used?

Horizontal expansion should be used when parts need to fit tightly together or when gaps are observed in printed assemblies.

How do I know if I need vertical expansion?

If your prints are coming out shorter than the intended height or if layers are not bonding properly, you might need to adjust vertical expansion.

Can I use both expansions together?

Yes, adjustments for both horizontal and vertical expansion can be used in conjunction to optimize the fit of 3D models and assemblies.